Raw material is checked by the quality team at the time of procurement and is tested at lab too. We have inhouse Laboratory to check the quality of the products. Our laboratory staff is well trained and highly efficient to carry out the tests. Mainly two types of analysis done at our laboratory. Physical analysis and chemical analysis. Currently we outsource products for Micro-Organism analysis and Pesticide residual analysis.

Fumigation process depends on the product requirement and the importing country’s norms. Raw material is placed in vacuum fumigation chamber and is treated with chemical ingredient ‘methyl bromide’. The concentration of the chemical depends upon the requirement of the product. Fumigation is the officially authorized procedure for the killing, removal or rendering infertile the pests. We strictly adhere to the following guidelines:

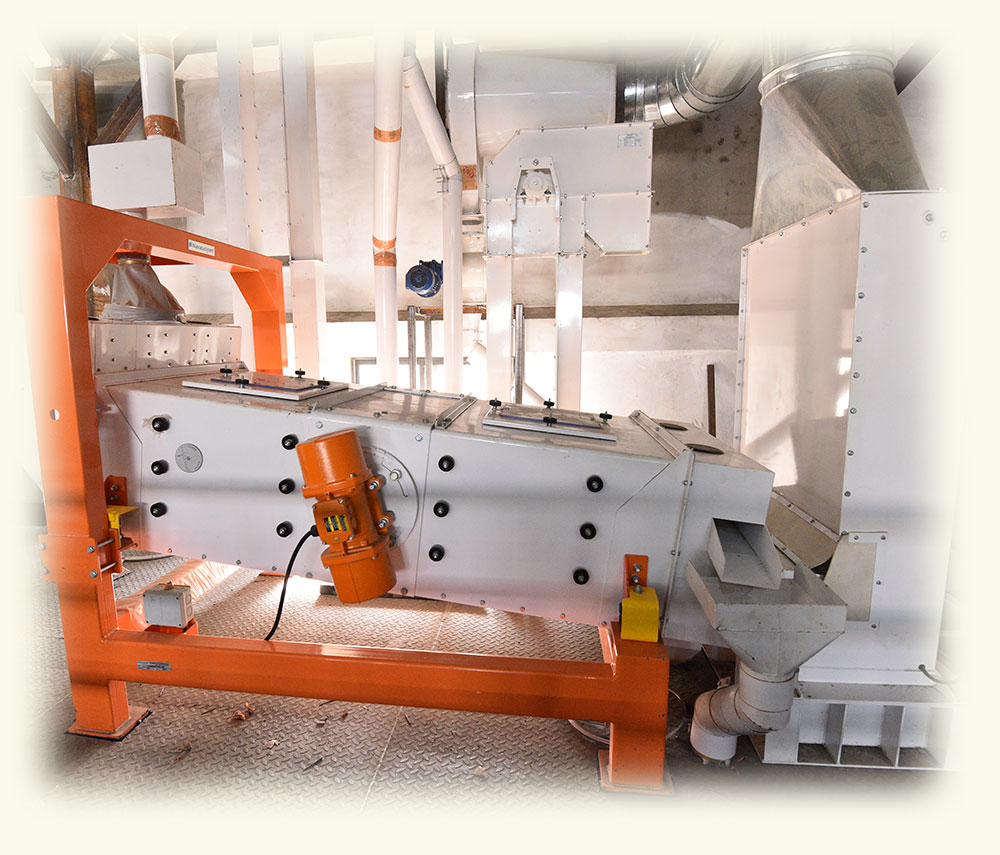

Hi-Tech Cleaning Plant is mainly used for Seed Spices, Pulses and Grain. This Comprises various steps of Separator Classifier, De-stoner, Magnetic Roller and Sortex

This is a method of food processing where big chunks or grains of food are ground to powder. We have a world-class “chakki” for wheat and pulses grinding which produces perfect flour for use or as a best ingredient for perfect recipe. In sieving, the size of the product is matched with the mesh size.

Sterilization is a controlled heating process used to control the microorganisms counts like bacteria, yeast and molds. It also helps retain flavors, colors and texture of the products.

Sterilization is the process where product kept at high pressure with steam either in batch or continuity. This process enhances color and texture of the product.

We provide Steam sterilized or Gamma Radiated material as per the buyer’s requirements.

Packing is the last step of the food processing. The product packing practice is following all the hygiene measure. Packing involve some of the process as below